About Rereads

What is a “Reread”?

In the event a dosimeter is mishandled, placed in the holder incorrectly, is dirty, is damaged, or if a measurement value is different than expected, it is important to have a controlled process that allows the user to “reread” (i.e., re-measure) the dosimeter.

For example, if the technician reads a dirty dosimeter the resulting dose measurement will not be accurate. The technician can carefully wipe or flick dust off the dosimeter and then re-read the dosimeter, and the new (correct) dose measurement will be seen on the final dosimetry report.

What happens to the dosimeter’s measurement during a reread?

IMPORTANT!

A dosimeter’s original measurement and all subsequent re-read measurements are permanently recorded by the software, and measurement events are logged in the audit trail (FDA 21 CFR part 11 compliant). The dosimeter’s original measurement information is not lost or overwritten.

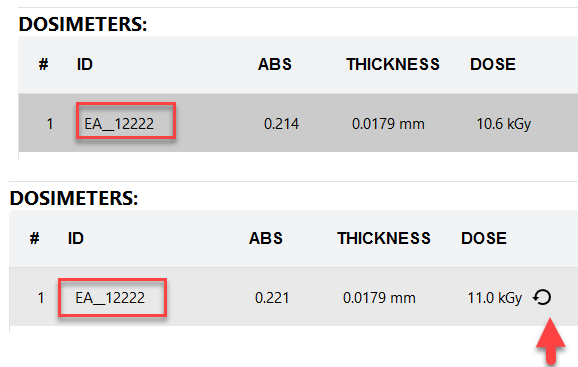

The re-read measurement value replaces the original measurement in the dosimetry report,on the measurement screen, in the exported reports (Excel and PDF), and in the export tables (for integrated systems.) On the measurement screen, a reread symbol appears next to the dosimeter’s dose value.

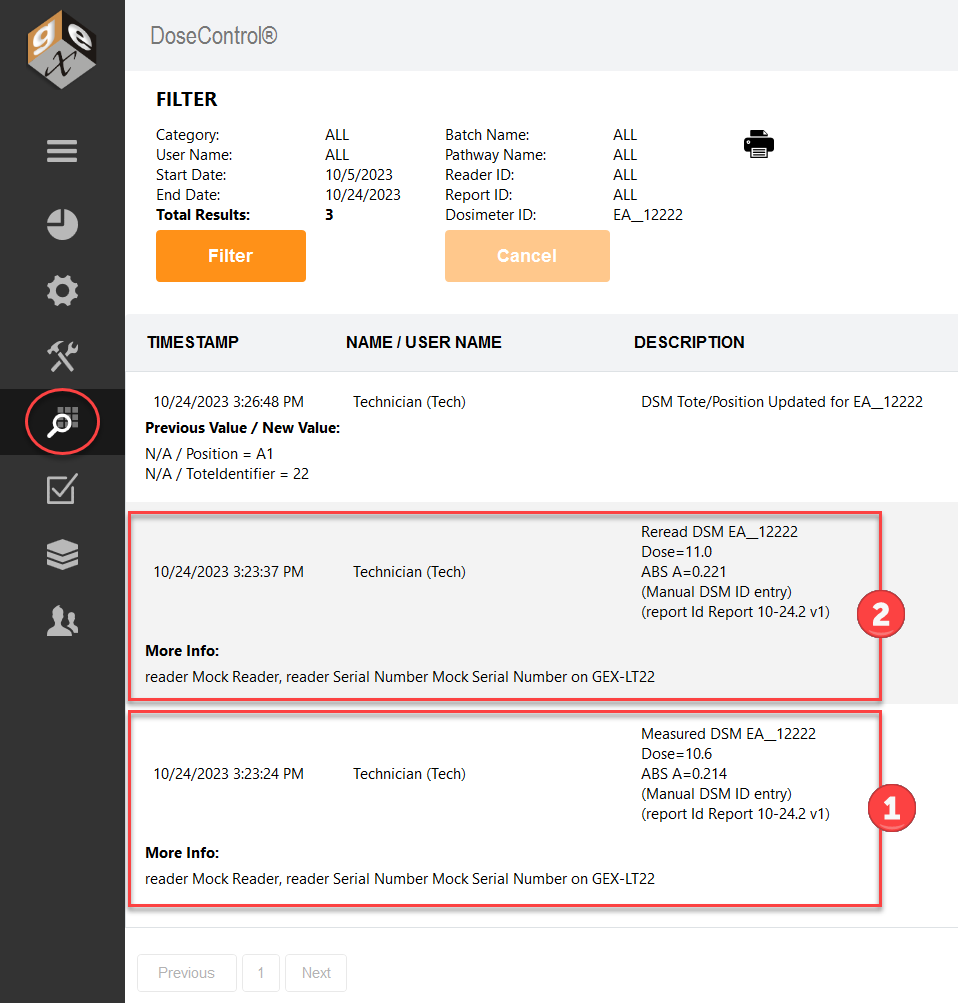

All measurements (original and rereads) are logged in the audit trail (screenshot below, 1 is the original measurement, 2 is the reread measurement).

Dosimeter EA_12222 original measurement and reread measurement with icon.

Audit trail for dosimeter EA_12222 measurements

Who can setup the Reread parameters?

The Application Admin can setup Rereads in DoseControl to control how users can re-read a dosimeter.

By default, DoseControl software allows unlimited re-reads (re-measurements) of a dosimeter, and each re-read absorbance measurement replaces the previous measurement in the dosimetry report.

Reread Methods - “Simple” and “Statistical”

Simple Reread

The user will take a measurement which will replace the original measurement on the screen.

Statistical Rereads

A statistical reread session requires the technician to make three measurements of the dosimeter and, if desired, allows a statistical evaluation of the results to determine if the reread data supports accepting the original measurement or supports changing the original measurement. You can choose to include or exclude the original measurement in the statistical evaluation.

If the results of the statistical reread session pass the statistical evaluation, the new dose result replaces the original dose measurement on the screen, in reports, and in exported data.

Control Reread parameters

The Application Admin can setup different requirements and restrictions for the dosimeter re-read process, if desired. An overview of what the Admin can configure for re-reads:

User permissions: Restrict re-read activity to specific users given a re-read role.

Define if multiple users are required to do a re-read: Require a different user to login and perform the re-read.

Define reasons for re-reads: Admin define “reasons” allowed for the user to perform a re-read of a dosimeter. These reasons will be available to the technician in a drop-down menu. A reason is selected, and the user can then perform a re-read.

Define if and how a re-read measurement replaces the original measurement: The software allows for two re-read methods, “Simple rereads” and “Statistical rereads”

Define how many re-reads can be performed for a dosimeter: The Admin can limit the number of times a user can re-read a dosimeter.

Define if a comment is required by the user performing the re-read.

CAUTION

Once a re-read reason is used for a dosimeter, the user cannot ever select a different reason. If the reread is interrupted, the software retains the position of any reread sequence so that it can enforce the number of allowed rereads. Therefore, users need to be properly trained to make their selection of the reason for rereading because failure to do so may limit the available workflows to reread that dosimeter again.

What does the Reread workflow look like to the Technician?